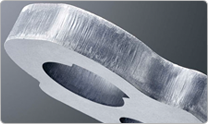

Tools & Molds

With the

staggering replacement cost of industrial tools and manufacturing injection

molds, the ability to repair tools and molds brings a welcome financial relief

to any company. But traditional welding processes have made this very

difficult due to the hardened metal used in most hand tools, and the delicate

nature of industrial equipment and injection molds. The intense heat created by

traditional welding can cause these items to crack and distort.

With the

staggering replacement cost of industrial tools and manufacturing injection

molds, the ability to repair tools and molds brings a welcome financial relief

to any company. But traditional welding processes have made this very

difficult due to the hardened metal used in most hand tools, and the delicate

nature of industrial equipment and injection molds. The intense heat created by

traditional welding can cause these items to crack and distort.

But not with Laser Fix Topanga’s cutting-edge laser welding technology. The low-heat, pulse laser welding of our state-of-the-art 6V Super Duty Laser Welder ensures precision- quality repairs, and avoids the issues caused by Arc Welding’s extremely high temperatures.

Laser welding also streamlines repairs into a single-step process- as opposed to the 3 step pre-heating welding and post-welding treatments required with traditional welding— we repair your items quickly, and get you back to work fast!

We realize your business can’t run without your tools or injections molds—that’s why Laser Fix Topanga guarantees super-fast turnaround times! Most repairs are complete within 1 to 2 days of your package arriving at our facility, and we cover all shipping costs—both shipping items to us and returning the finished product to you!